plug flow reactor solved problems pdf

1-11 Strategy to Solve This Problem The. General Algorithm for Solving Isothermal Reactor Problems.

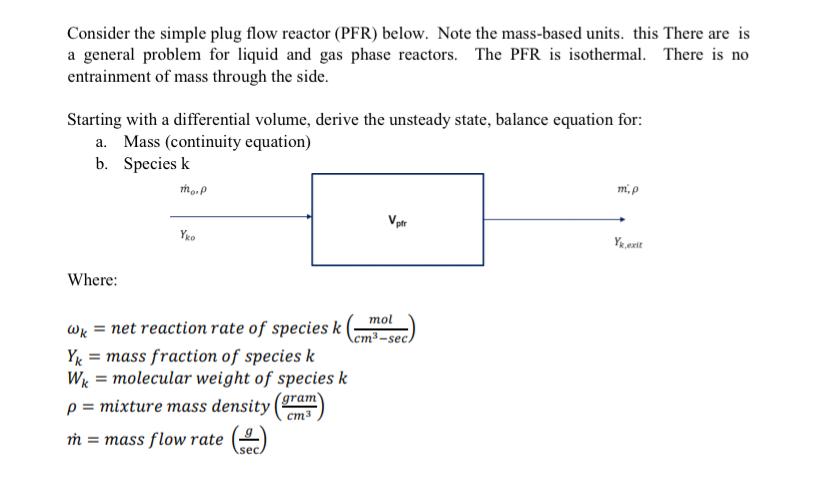

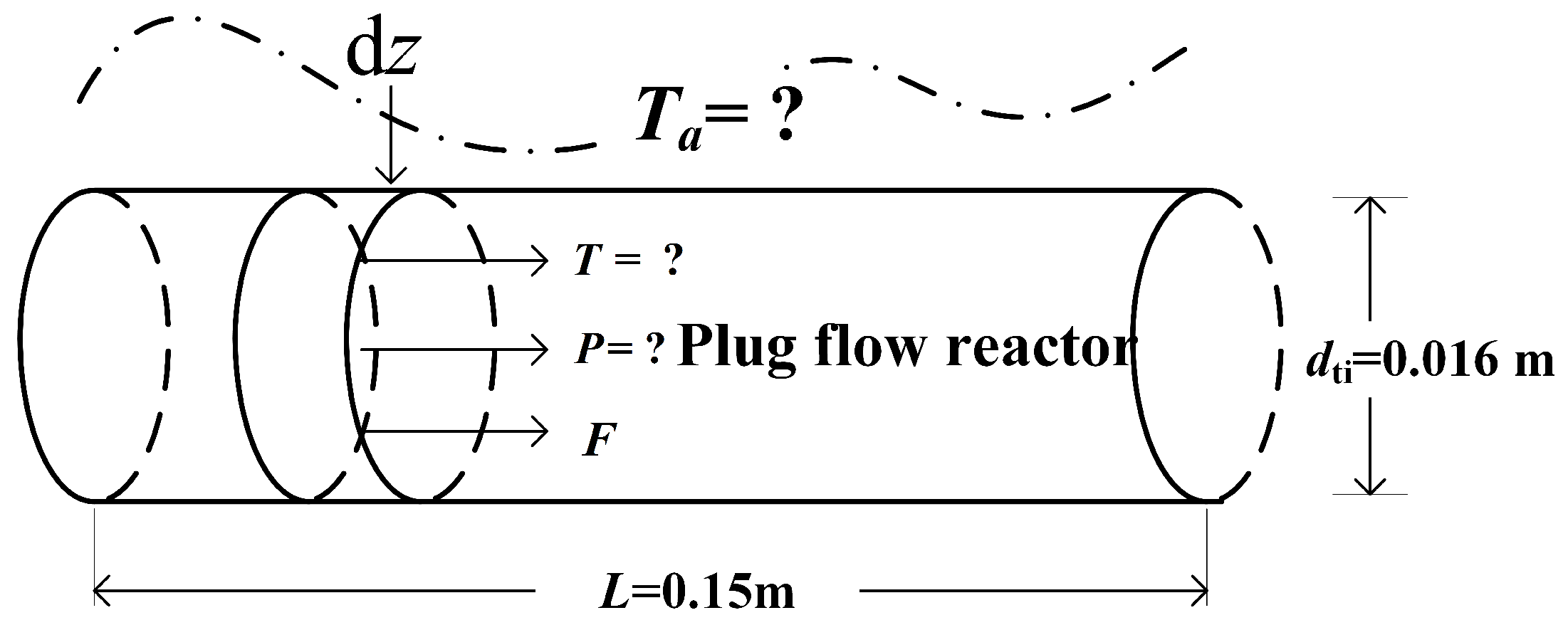

Pdf Ideal Plug Flow Reactor Characteristics Of Ideal Plug Flow Perfect Mixing In The Radial Dimension Uniform Cross Section Concentration No Mixing In The Axial Direction Or No Axial Dispersion Segregated Flow

Determine the volume of plug flow reactor that would be necessary to achieve 50 conversion of the liquid butadiene assuming isothermal.

. The temperature in the reactor is prescribed a. Flows into the reactor and is then converted into the product. The reaction 𝐴𝐴 𝑅𝑅 is first order on reactant A.

Integrate 8 or 13 and find extent along the reactor. General Mole Balance Equation GMBE 2. Basic types of problems 1.

The reaction in the slice of fluid is analogous to the reaction in a batch reactor. The plug flow reactor is the second-most primary ideal reactor and is similar to the continuous stirred tank bioreactor. Debasree Ghosh Lecture notes on Polymer Reaction Engineering Module II.

By a certain chemical reaction. 9 or 14 find the heat. Problem 2 In an isothermal batch reactor 70 of a liquid reactant is converted in 13 minutes.

Diagram of a pipe showing pressure upstream and downstream. Solve problems in chemical reactor design. Plug flow reactors volume.

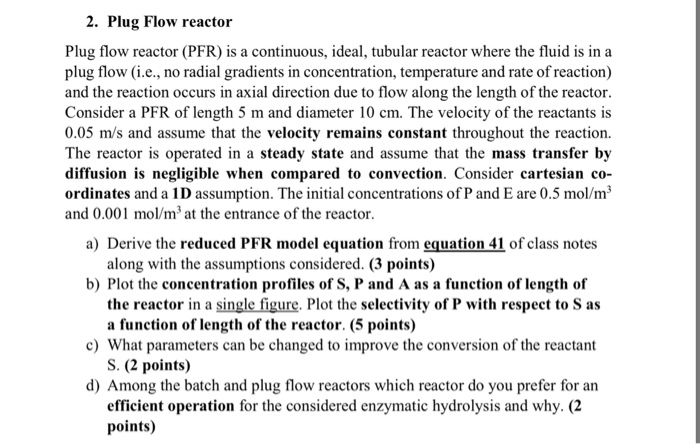

Your answer by calculating the reactor volume in liters and the outlet molar flow rate of triethanolamine that correspond to your design. What space-time is required to effect this. 2Assuming these assumptions are all met calculate the plug flow reactors volume to achieve a 60.

This will open up COMSOL library where you see many COMSOL files to solve chemical reaction engineering problems. Has an inlet flow composed of the reactants. Small solid particles of product B are entrained in the gas flow.

The plug flow reactor. B is equal to 12110-3 m³molks at 20oC. PV NRT C P i RT P F C i turns Fs into.

Design of Ideal Reactors Plug-flow reactor PFR A plug-flow reactor PFR may be used for both liquid-phase. D If the desired conversion is 85 find the minimum reactor volume and the desired heat removal rate along the reactor. Flow is driven by the pressure drop across the pipe.

As a slice of fluid progresses through the reactor the reactants are converted to products. Rate Laws Write down rate law in terms of limiting reactant. Find Nonisothermal Plug Flow Reactor-Adiabatic.

The rate constant is 030 mol -1. An isothermal plug flow reactor is used for the reaction 10A g B s. The reactor necessary to maximize exit conversion.

Here polymerization and conversion reactions are performed in. The document is not exhaustive and contains only a brief introduction to the material and energy balance in chemical reactors. The main aim is to.

Determine The required detention time and the required volume if the removal or conversion of A is 90. If the reactor is a batch reactor calculate the required reaction time if the. P 0 P final Figure 4.

Clearly state all assumptions used in your derivation. Tz To isothermal reactor.

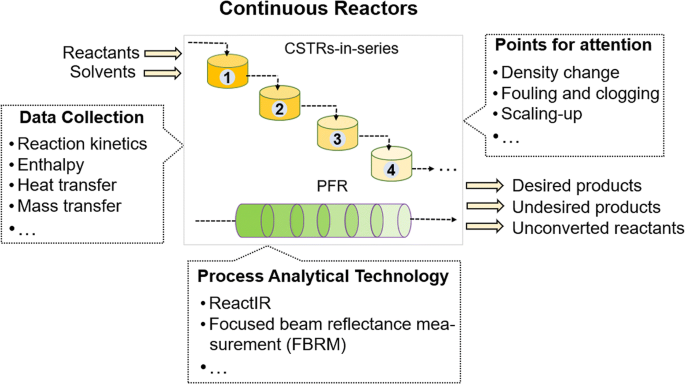

Reactor Design And Selection For Effective Continuous Manufacturing Of Pharmaceuticals Springerlink

Reactor Design And Selection For Effective Continuous Manufacturing Of Pharmaceuticals Springerlink

Pdf Reactor Design Chizurum Ezeocha Academia Edu

Establishment And Performance Of A Plug Flow Continuous Hydrothermal Reactor For Biocrude Oil Production Sciencedirect

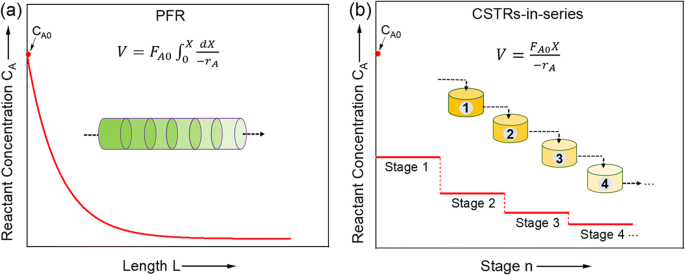

Chemengineering Free Full Text Understanding Catalysis A Simplified Simulation Of Catalytic Reactors For Co2 Reduction Html

Solved Consider The Simple Plug Flow Reactor Pfr Below Chegg Com

An Inclined Plug Flow Reactor Design For Supercritical Water Oxidation Sciencedirect

Plug Flow Reactor An Overview Sciencedirect Topics

Process Modelling Simulation And Control For Chemical Engineers Solved Problems Chapter 9 Laplace Domain Dynamics Francisco Angel Academia Edu

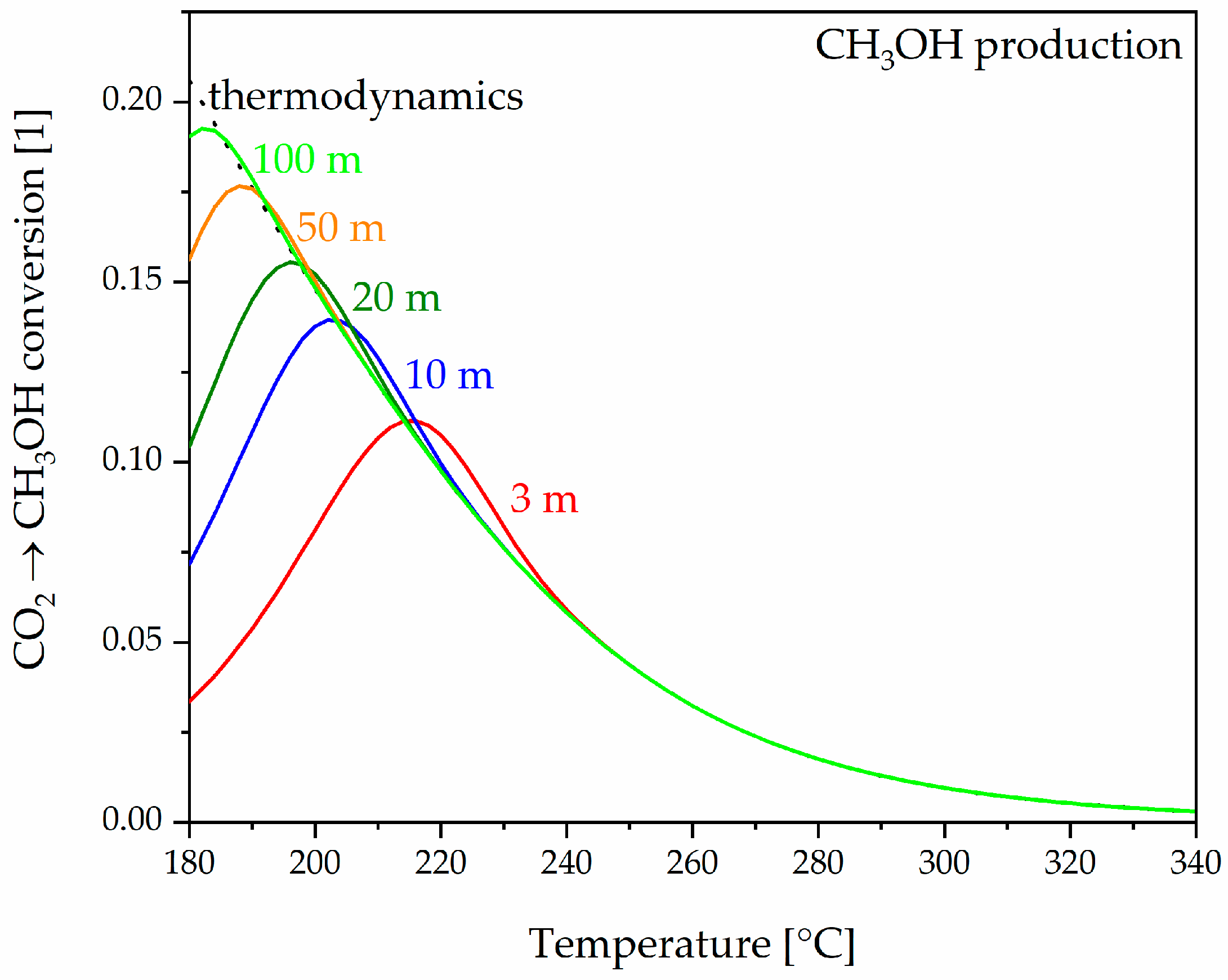

Entropy Free Full Text Entropy Generation Rate Minimization For Methanol Synthesis Via A Co2 Hydrogenation Reactor Html

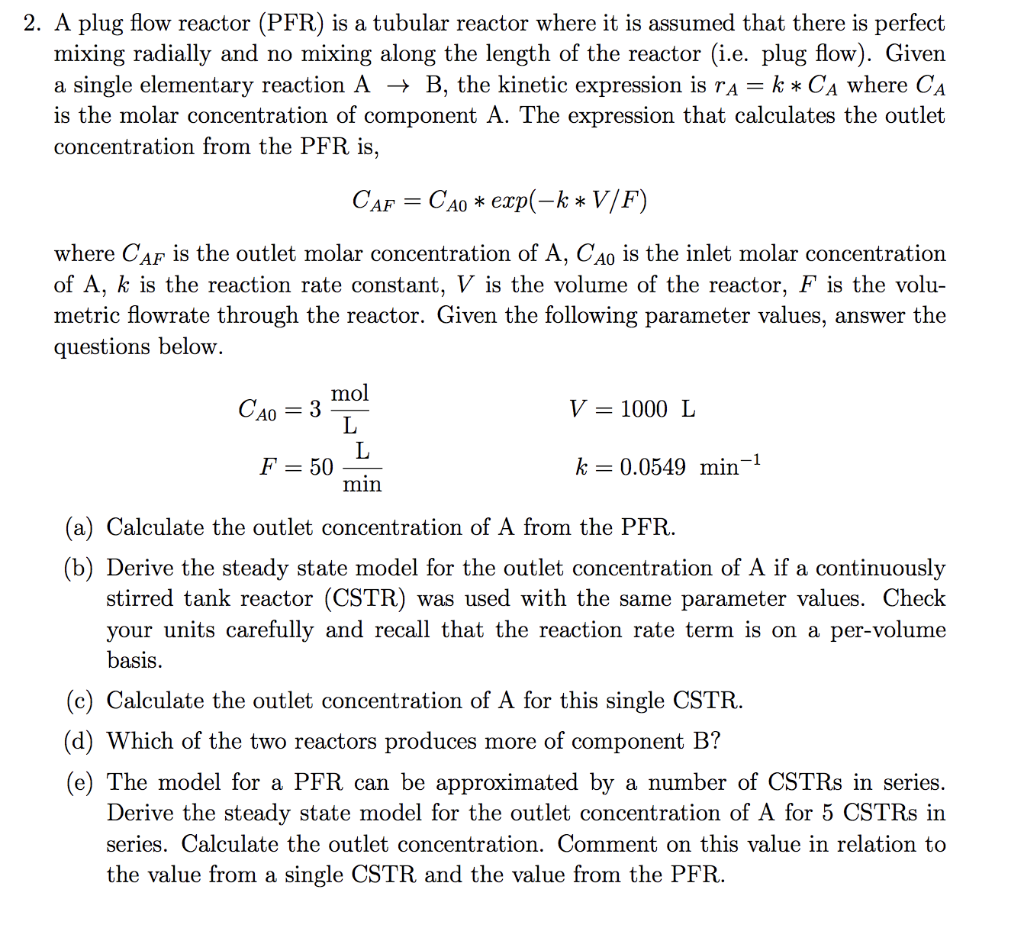

2 Plug Flow Reactor Plug Flow Reactor Pfr Is A Chegg Com

Coil In Coil Reactor Augmenting Plug Flow Performance By Combining Different Geometric Features Using 3d Printing Industrial Engineering Chemistry Research

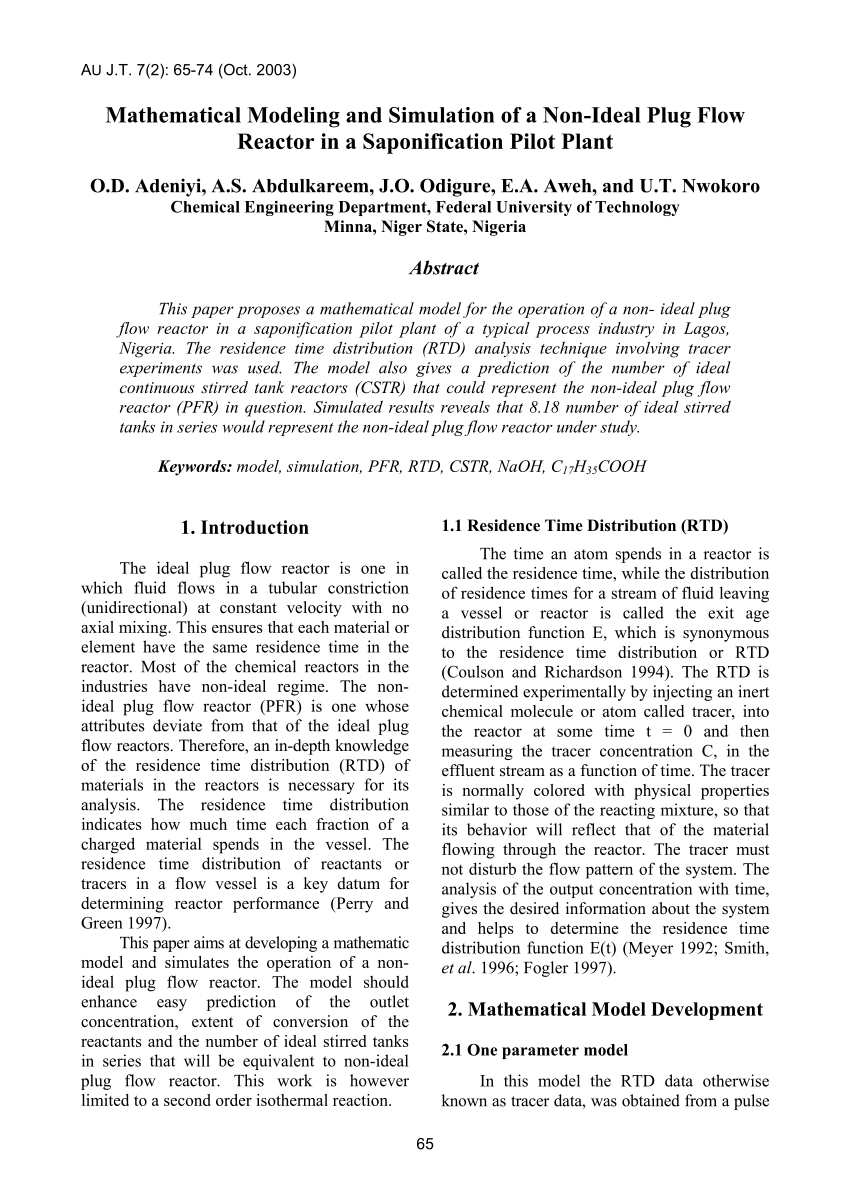

Pdf Mathematical Modeling And Simulation Of A Non Ideal Plug Flow Reactor In A Saponification Pilot Plant

An Inclined Plug Flow Reactor Design For Supercritical Water Oxidation Sciencedirect

Pdf Aspen Plus Simulation Of Saponification Of Ethyl Acetate In The Presence Of Sodium Hydroxide In A Plug Flow Reactor